数控机床可以做很多事情,但最令人兴奋的是数控雕刻。使用CNC在木材、金属或任何其他材料上创建精细的细节是令人满意的。

Table of Contents:

- What is CNC Engraving?

- How Does CNC Engraving Work?

- What are the Processes of CNC Engraving?

- What Materials Can Be Used for CNC Engraving?

- Advantages and Disadvantages of CNC Engraving

- Applications of CNC Engraving

- Conclusion

Numerically controlled machines can do many things, but one of the most exciting is CNC engraving. Creating fine details on wood, metal, or any other material using CNC is satisfying. Most importantly, achieving these results through machines is much easier than manually.

Just like in the past, most of today’s engraving processes are for decorative purposes. However, due to technological advancements, today’s engraving processes are much more efficient. In this article, we will delve into the CNC engraving process, identifying its types and applications in the industry.

1. What is CNC Engraving?

CNC engraving involves using computer-controlled machines to impart designs and logos onto materials. This process can be used for artistic purposes and to mark parts in an industrial setting. Manufacturers of signs and jewelry may also use CNC engraving machines for CNC engraving.

Most CNC machines can support engraving. However, certain machines (such as CNC milling machines) have additional features that can simplify and enhance the engraving process. Nevertheless, some standard features can be found in any CNC engraving machine. For example, the machine should have a high-speed spindle.

2. How Does CNC Engraving Work?

The CNC engraving process follows these basic steps:

Step ①: Prepare the Design

CNC machines rely on computer control to engrave surfaces. To enable the cutting tool to engrave the desired surface, the CNC machine must have a program. The design must be transmitted to the machine as a first step.

Many CAD software options are available, such as CorelDRAW and AutoCAD. When designing engraving details in the software, optimize the design. Using the correct scale is also important.

You need to import the engraving design into the CNC machine. The CNC machine should have a manual on how to perform this import.

Step ②: Set Up the CNC Machine

Now that the design is ready and imported into the CNC machine, you’re almost ready to start engraving. However, this is only after ensuring everything on the machine is set up.

Ensure that the workpiece is securely and correctly fixed on the machine.

Step ③: Run a Test Engraving

Test the program to ensure it works and the CNC machine is operational. Run this test on a separate workpiece with similar properties to see the expected results.

Step ④: Execute the Engraving Process

If the test engraving is good, you can proceed with the actual engraving process. You need to monitor the process closely as it progresses. Potential issues that may arise during engraving include:

- Loss of accuracy

- Engraving too shallow or too deep

- Tool dulling or breakage

You may need to adjust the settings on the CNC machine based on how the workpiece or cutting tool responds.

Step ⑤: Finish the Process

The engraving action may not be complete until the engraved part undergoes surface finishing and quality checks. A quality brush is enough to remove debris from the surface. Polishing the engraved sections may be necessary to enhance appearance and durability.

Quality control is usually the final stage of the CNC engraving method. Here, you will review specific aspects of the item concerning set standards. These checks target elements such as surface quality, cutting depth, and the accuracy of engraving features.

3. What are the Processes of CNC Engraving?

CNC engraving processes more or less follow the basic steps mentioned above:

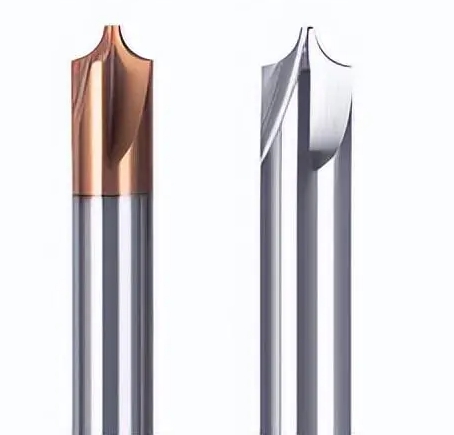

CNC Diamond Drag Engraving

The main feature of this type of CNC engraving machine is the diamond-tipped tool. Through scratching, the extremely tough diamond easily engraves the material. Due to the toughness of diamonds, this method can engrave almost any material.

CNC Laser Engraving

In CNC laser engraving technology, a powerful laser beam strikes the material, causing sublimation. This leaves marks on the surface. CNC technology controls the laser head’s movement.

CNC Rotary Engraving

This machine features a rotating cutting tool. The tool has grooved edges that help cut the material. The tool’s tip can be round or V-shaped. To achieve this tool rotation, the machine is equipped with a unique spindle design. CNC rotary engraving machines are highly versatile.

4. What Materials Can Be Used for CNC Engraving?

As a versatile machining method, CNC engraving is suitable for a wide range of materials. Of course, the first category of materials on the list is metals. Common metals used for CNC engraving include copper, aluminum, and stainless steel.

You can also engrave various types of plastics, including polystyrene, polyethylene, and ABS.

Wood can also be CNC engraved. Types of wood that can be engraved include softwood, hardwood, and cork.

5. Advantages and Disadvantages of CNC Engraving

Advantages of CNC Engraving:

Accuracy – One of the many advantages of CNC engraving machines is high precision. They can produce a large number of parts and designs without losing the original level of detail. This high precision is crucial for aerospace and other sensitive applications.

Versatility – To enhance accuracy, CNC engraving machines are suitable for different materials and designs. In addition to metals like aluminum, you can engrave wood, plastics, and other materials to achieve complex designs.

Speed – CNC engraving combines precision with speed. As long as you have the correct CNC program, you can quickly produce many parts.

Replication – If you want to produce multiple identical parts, CNC engraving is a suitable process.

Disadvantages of CNC Engraving:

High Capital – CNC engraving machines are relatively expensive. However, the resulting production costs are manageable.

Machine Maintenance – CNC machines are highly technical and require proper maintenance, which can be both complex and costly.

Skilled Operation – In terms of maintenance, the technical level of CNC engraving machines requires advanced operational skills.

6. Applications of CNC Engraving

CNC engraving technology is highly useful in the following fields:

Industrial Marking – The markings of CNC engraving are extremely wear-resistant. They outperform markings made by chemical etching, ink, and adhesive labels.

Jewelry Making – CNC machine engraving has revolutionized the jewelry industry through laser engraving, deep engraving, and other methods. The results are reliable and of high degree.

Sign Making – With CNC engraving machines, you can easily create 3D cutouts. With the invention of this CNC machining method, sign-making has never been the same.

Conclusion

From this article, it is clear that CNC engraving is an interesting and important manufacturing process. Equipped with the right CNC equipment and skills, you can achieve a lot through this method.

Author: Yao Guang has 8 years of engineering experience, proficient in the machining properties and surface finishing processes of various materials. He has been involved in developing over 100 complex injection molding and CNC machining projects. He is passionate about sharing his knowledge and experience.