Nickel plating and chrome plating are two of the most popular choices when it comes to surface treatments for metal products. Both processes prevent corrosion, improve durability, and add beauty, but they have distinct differences in performance and application. If you’re deciding between nickel or chrome for your next project, it’s important to understand the benefits and limitations of each process. Let’s dive into the details.

What is Nickel Plating?

Nickel plating involves depositing a layer of nickel onto a metal surface. This can be achieved through two main methods: electroplating and chemical plating. Electroplating requires an electric current to adhere the nickel to the substrate, while chemical plating relies on a chemical process without the passage of electricity. The resulting finish can range from matte to glossy, depending on the desired effect.

Nickel plating is valued for its versatility and functional benefits. It offers excellent corrosion resistance, especially in environments exposed to moisture or chemicals. In addition, it provides a smooth surface that is ideal for reducing friction in mechanical parts.

Common applications for nickel plating include:

ØAuto parts such as fuel injectors and gears

ØElectrical connectors and terminals

ØKitchen utensils and tools

What is Chrome Plating?

Chrome plating or chrome plating is a process that coats a metal surface with a thin layer of chrome. Like nickel plating, chrome plating can also be done through electroplating. The chrome layer is known for its striking reflective appearance and high hardness.

In addition to its aesthetic, chrome plating offers exceptional durability. It resists rust and wear, making it suitable for heavy-duty applications. The finish is also easy to clean, which adds to its appeal in both decorative and functional uses.

Common applications for chrome plating include:

Ø Motorcycle and automobile parts, such as bumpers and exhaust pipes

ØBathroom fixtures, including faucets and shower heads

ØIndustrial equipment and machinery parts

Comparing Nickel Plating and Chrome Plating

While both nickel and chrome plating have protective and decorative properties, they differ in several key ways:

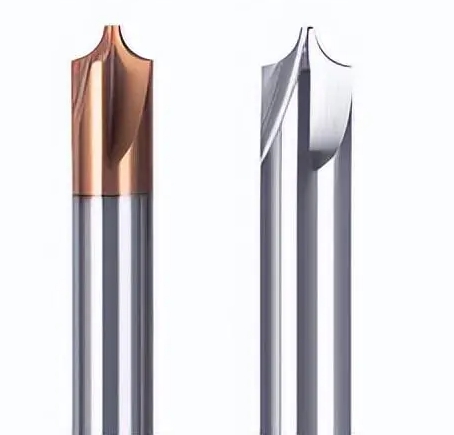

1. Appearance:

Ø Nickel plating can range from a dull to a bright finish, depending on the application process and additives used. It typically has a warmer yellow hue.

Chrome , on the other hand, is noticeably bright and reflective, with a blue undertone, making it a popular choice for high-end aesthetics.

2. Durability:

ØNickel plating offers excellent corrosion resistance but may wear faster in abrasive environments.

Ø Chrome plating is harder and more scratch-resistant, making it ideal for high-friction or heavy-use applications.

3. Cost:

Ø Nickel plating is generally less expensive than chrome plating, especially for projects that require large surface areas.

Ø Chrome plating tends to cost more because of the complex process and the high requirements for its polished appearance.

4. Environmental impact:

ØThe chemicals used in nickel plating can pose risks to the environment if not handled properly, but are considered less hazardous than chromium.

ØChromium plating, especially hexavalent chromium, involves toxic substances and requires strict supervision and safety measures.

5. Application:

ØNickel is often used for functional purposes, such as improving wear resistance or electrical conductivity.

ØChromium is favored for its decorative appeal and toughness under extreme conditions.

Which should you choose?

The choice between nickel and chrome plating depends largely on the specific requirements of your project. If you prioritize cost-effectiveness, corrosion resistance, or functionality, nickel plating may be a better choice. On the other hand, if aesthetics, scratch resistance, or a high-end appearance are your primary considerations, chrome plating may be your best choice.

Consider the environment in which the plated item will be used. For example, in marine or chemical environments, nickel plating will provide better protection against corrosion. Conversely, for parts that need to withstand mechanical wear or maintain a bright surface over a long period of time, chrome plating is a better choice.

Nickel and chrome plating each have advantages and disadvantages and are suitable for different applications. By weighing appearance, durability, cost and environmental factors, you can determine which surface treatment best meets your needs.

Whether you are working on a mechanical part, decorative item, or industrial tool, understanding the differences between nickel and chrome plating will help you make an informed decision. Both finishes can enhance the performance and appearance of your project, ensuring it will stand the test of time.